Control & Signaling

- Popular first

- Lowest Price

- Highest price

- Name (A - Z)

- Name (Z - A)

- Date (lowest)

- Date (highest)

Application of Control & Signaling Products Across Industry Sectors

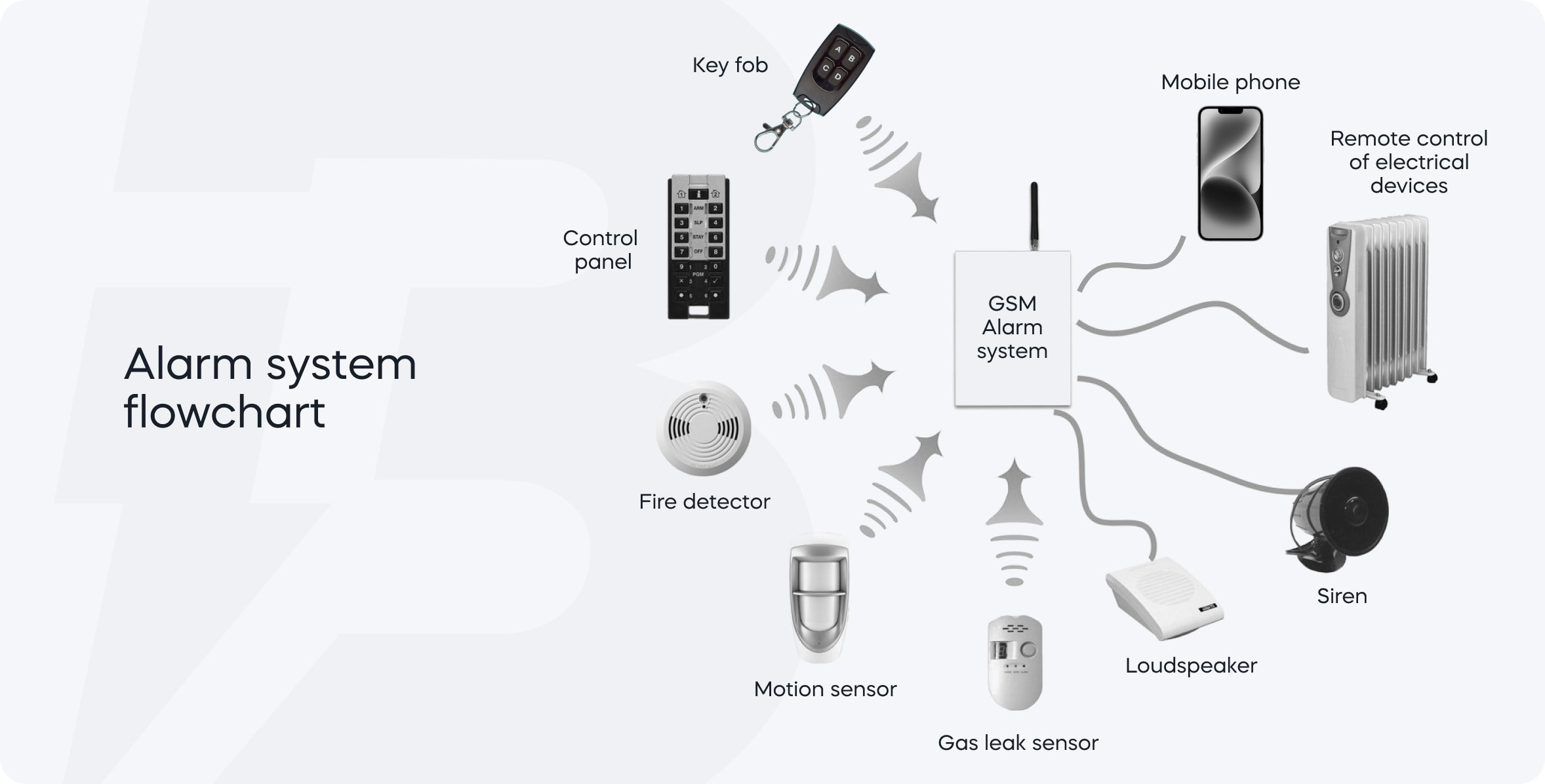

The "Control & Signaling" category encompasses essential components designed to optimize and streamline industrial processes, ensuring efficient management, safety, and automation across a variety of sectors. Leading European manufacturers provide these products with the highest standards of quality and reliability, making them ideal for rigorous industrial demands. Control and signaling devices play a crucial role in monitoring, controlling, and safeguarding industrial equipment and personnel, thus enhancing overall productivity and reducing downtime.

Key Applications of Control & Signaling Products

Manufacturing and Assembly Lines In manufacturing environments, efficiency and precision are vital. Control and signaling devices, such as pilot lights, pushbuttons, and emergency stops, are essential for monitoring operational status and signaling malfunctions or safety concerns. These products allow operators to easily start, stop, or adjust equipment functions, facilitating quick responses to errors or process changes. The enhanced control over machinery helps minimize disruptions, optimize workflow, and improve overall safety on the factory floor.

Power Generation and Distribution

In the power generation sector, where consistent performance and safety are critical, control and signaling equipment provide the necessary interface between operators and complex electrical systems. Devices like signal towers, indicator lights, and selector switches enable quick assessment of equipment conditions and system statuses, making it easier to identify and resolve issues before they escalate. In environments where high voltage and heavy machinery are in constant use, these products contribute to safer operational standards and more efficient energy distribution.

Oil & Gas

Control and signaling products are indispensable in the oil and gas industry, where equipment operates in high-risk and challenging conditions. In this sector, specialized control devices are used to monitor pumps, compressors, and pressure levels, ensuring that each element of the process remains within safe operating parameters. Explosion-proof and corrosion-resistant options are often required to meet industry-specific standards. Signal towers, emergency stops, and alarms provide timely alerts to operators, enabling swift action in the event of equipment failure or process deviations, thus enhancing both safety and compliance.

Mining and Heavy

Industries Mining and heavy industries require durable and resilient control and signaling equipment to withstand extreme environments and high mechanical loads. Control panels, indicator lights, and ruggedized switches are used extensively to manage heavy machinery, conveyors, and extraction systems. Control products designed to operate under high temperatures, dust, and moisture contribute to smoother operation and reduced risk of machine wear and tear. This equipment is critical in maintaining high productivity and ensuring personnel safety in these challenging settings.

Water Treatment and Waste

Management In water treatment plants and waste management facilities, control and signaling devices enable operators to monitor treatment processes closely, including flow rates, pressure, and chemical levels. By utilizing control panels and indicator lights, operators can assess the status of pumps, filtration systems, and other critical components in real-time. These products are vital for maintaining regulatory compliance and environmental standards, allowing facilities to function effectively and meet strict operational requirements.

Automotive Industry

The automotive industry relies on precise and reliable control and signaling systems throughout the manufacturing process. Products like signal lights, selector switches, and emergency stops play a significant role in assembly line automation and quality control. These devices help ensure the safe and efficient movement of materials, monitor equipment conditions, and reduce human error. Control and signaling solutions tailored for automotive applications improve production line safety, streamline workflows, and increase overall output by supporting both robotic and manual assembly systems.

Pharmaceutical and Chemical

Industries In industries where precision and safety are paramount, such as pharmaceuticals and chemicals, control and signaling devices ensure strict adherence to process parameters. Products like indicator lights, alarm systems, and pushbutton controls help operators monitor reaction stages, maintain critical environmental conditions, and control hazardous processes. For equipment used in potentially explosive or corrosive environments, specialized signaling devices meet stringent safety and compliance requirements. These control solutions help prevent contamination, enhance safety, and guarantee the quality of products.

Assortment Control & Signaling in BaltElec

At BaltElec, our online store stands out for offering a comprehensive assortment of control and signaling equipment sourced from the top European manufacturers. Our product range is designed to cater to diverse industrial and commercial needs, ensuring reliability and efficiency in various applications.

Control & Signaling Products Overview:

- Control Equipment: This category includes devices used to control and manage electrical systems. Products such as contactors, relays, timers, and programmable logic controllers (PLCs) fall under this category. These components are essential for automating processes, switching operations, and ensuring smooth functionality in electrical systems.

- Signaling Equipment: These products are used to provide visual and audible indications of system status or faults. Items like indicator lights, buzzers, alarms, and signal towers help in monitoring and alerting operators about the operational state of equipment.

Each product in our assortment is carefully selected for its quality, performance, and compatibility with various industrial standards. We ensure that all products meet rigorous European standards and are backed by robust warranties, providing our customers with peace of mind.

Types of Products in the Control & Signaling Category

Control Equipment:

- Contactors: Electromechanical switches used for switching electrical circuits. They are crucial for controlling large electrical loads and are available in various sizes and configurations.

- Relays: Devices used to control a circuit by opening and closing contacts in another circuit. Relays are fundamental in automation for switching operations and protecting circuits.

- Timers: Used to control the duration of operations in electrical systems. Timers can be programmed for various intervals and are essential for tasks that require precise timing.

Programmable Logic Controllers (PLCs): Industrial computers used to automate processes. PLCs are highly customizable and can control complex operations through programming.

Signaling Equipment:

- Indicator Lights: Provide visual feedback about the status of equipment. These lights are available in different colors and intensities to indicate various operational states.

- Buzzers and Alarms: Auditory signals that alert operators to equipment status or faults. Buzzers are typically used for alerting to minor issues, while alarms signal more critical conditions.

- Signal Towers: Multi-colored towers that combine indicator lights and alarms to provide a comprehensive status overview. These towers are often used in industrial settings to monitor multiple conditions simultaneously.

Advantages of Buying Control & Signaling Equipment from BaltElec

- Wide Selection: At BaltElec, we offer an extensive range of control and signaling equipment, ensuring that you find exactly what you need. Our inventory includes both standard and specialized products, accommodating various industrial requirements.

- High Quality and Reliability: We source our products from leading European manufacturers known for their high standards of quality and reliability. Each product is rigorously tested to ensure it meets or exceeds industry standards.

- Competitive Pricing: Our pricing is designed to offer the best value for high-quality products. We leverage strong relationships with manufacturers to provide competitive prices without compromising on quality.

- Expert Support: Our team of experts is available to assist with product selection, technical support, and application advice. We ensure that you get the right equipment for your specific needs and offer guidance throughout the purchasing process.

- Efficient Delivery: With our streamlined logistics, you can expect prompt delivery of your orders. We maintain a well-managed inventory to ensure that popular products are always in stock and ready to ship.

Control & Signaling from Leading Manufacturers

- Schneider Electric: Schneider offers a range of reliable contactors, relays, and signaling devices. Their products are known for their durability and advanced features, such as the EasyPact series of contactors and the Zelio range of relays, designed for various automation tasks.

- ABB: ABB provides high-performance contactors and relays suited for industrial applications. Their offerings, like the ABB Ability Smart Sensor and the CT series of relays, are designed for efficiency and integration into modern automation systems.

- APC: APC, a brand by Schneider Electric, specializes in signaling equipment such as alarms and indicator lights. Their products are known for their robustness and suitability for critical signaling applications.

- Finder: Finder is renowned for its wide range of relays and timers. The Finder 40 series of relays and the 12 series timers are popular choices for their reliability and versatility in various control applications.

- Hager: Hager offers a variety of control and signaling devices, including their well-regarded signaling towers and relays. Their products are designed for ease of use and integration into existing systems.

- Legrand: Legrand’s control and signaling solutions include a range of indicator lights and signaling devices. Their products are known for their quality and innovative design, providing clear and reliable signals.

- OEZ: OEZ provides a broad selection of contactors and relays, known for their durability and efficiency. Their products are designed for industrial applications requiring reliable performance.

- Phoenix Contact: Phoenix Contact offers a comprehensive range of control equipment, including PLCs and relays. Their products are celebrated for their innovative features and compatibility with modern automation systems.

- Siemens: Siemens’ control and signaling products include high-quality contactors, relays, and signaling devices. The Siemens Sirius range is well-regarded for its advanced technology and reliability.

- Wago: Wago is known for its PLCs and relays, which are designed for flexibility and ease of integration. Their products are suitable for various automation applications and are recognized for their precision and reliability.

Prices for High-Quality Control & Signaling

Pricing for control and signaling equipment varies based on the type and specifications of the product:

- Contactors: Typically range from €30 to €150, depending on the size, voltage rating, and features. Basic models are at the lower end, while advanced models with additional features command higher prices.

- Relays: Prices for relays can range from €20 to €100. Basic electromagnetic relays are more affordable, while specialized or solid-state relays with advanced features are more expensive.

- Timers: Standard timers are priced between €40 and €120. Programmable timers and those with additional functionalities can be on the higher end of this range.

- PLCs: Entry-level PLCs start around €200, with more advanced models reaching up to €1,000 or more. Prices depend on the complexity, number of I/O points, and programming capabilities.

- Indicator Lights: Generally priced between €10 and €50, based on the type (e.g., LED, incandescent) and features (e.g., size, color).

- Buzzers and Alarms: Buzzers typically cost between €15 and €60, while alarms can range from €30 to €100, depending on their loudness and features.

- Signal Towers: These devices are priced between €100 and €300, depending on the number of segments, light types, and additional features.

Guide and Tips for Choosing Products in the Control & Signaling Category

When it comes to industrial electrical equipment, the Control & Signaling category plays a critical role in ensuring the seamless operation of machinery and safety protocols. Selecting the right control and signaling products can greatly enhance efficiency, reduce downtime, and ensure compliance with safety standards. This guide aims to provide essential tips for making informed choices in this category.

Understanding Control & Signaling Equipment

Control & Signaling products encompass a range of devices that manage, control, and communicate the status of industrial systems. These include push buttons, switches, relays, indicators, and control panels. Understanding the functionality and application of each type of product is crucial for selecting the right equipment for your specific needs.

Define Your Requirements

Begin by clearly defining your operational requirements. Consider factors such as the type of machinery, the environment in which the equipment will be used (e.g., temperature, humidity, and exposure to contaminants), and the level of automation desired. Understanding these requirements will guide your selection process.

Evaluate Compatibility

Compatibility with existing systems is another critical aspect. Ensure that the products you choose are compatible with your current machinery and control systems. This includes checking voltage ratings, connection types, and communication protocols. It’s advisable to consult with the manufacturer or supplier to confirm compatibility, especially when integrating new equipment into an established system.

Assess Safety Standards

Safety is paramount in industrial environments. Verify that the Control & Signaling products you are considering meet relevant safety standards and certifications. Look for products that comply with international standards such as IEC, ISO, or local regulations. Investing in certified equipment not only ensures safety but can also prevent costly accidents and downtime.

Choose Quality Manufacturers

Opt for products from leading European manufacturers known for their reliability and innovation. Established manufacturers often provide detailed specifications, robust warranty options, and technical support, which can be invaluable when dealing with complex systems. Researching the manufacturer's reputation in the industry can provide insights into product quality and longevity.

Consider User-Friendliness

User interface and accessibility are essential factors, especially for control panels and signaling devices that require operator interaction. Look for intuitive designs that simplify the operation and maintenance of the equipment. Products equipped with clear labeling, ergonomic controls, and visual indicators can enhance usability and reduce the likelihood of operator error.

Review Technical Support and Documentation

Adequate technical support and comprehensive documentation are crucial when selecting Control & Signaling products. Ensure that the manufacturer or supplier offers extensive user manuals, installation guides, and troubleshooting resources. Access to knowledgeable technical support can also help resolve issues quickly, minimizing downtime.

Evaluate Cost vs. Value

While budget constraints are an important consideration, it is essential to evaluate the overall value of the products rather than just the initial cost. Cheaper alternatives may result in higher maintenance costs, lower efficiency, and shorter lifespans. Assessing the total cost of ownership (TCO) can provide a clearer picture of the long-term investment and potential savings.

Seek Recommendations

Don’t hesitate to seek recommendations from industry peers or experts. Networking with professionals who have experience with specific products can provide valuable insights into performance and reliability. Online forums, industry publications, and trade shows can also be excellent resources for gathering opinions and reviews.

Conduct Testing and Piloting

Before making a large-scale purchase, consider conducting testing or piloting of selected products. This approach allows you to evaluate the equipment’s performance in your specific environment and under actual operating conditions. It can help identify any potential issues before full-scale implementation.

-

Can I get technical support for installation and usage?

Yes, our team of experts is available to provide technical support and guidance on installation and usage. We offer assistance through phone, email, and our online chat service.

-

Do you offer bulk purchase discounts?

Yes, we offer discounts for bulk purchases. Please contact our sales team for more information on pricing and availability for large orders.

-

How do I choose between a mechanical and solid-state relay?

Mechanical relays are suitable for general-purpose applications and can handle higher currents. Solid-state relays offer faster switching, longer life, and are ideal for applications with frequent switching or harsh environments.

-

What factors should I consider when selecting a contactor?

Consider the voltage and current ratings, the type of load (resistive or inductive), and the environment where the contactor will be used. Ensure compatibility with your existing electrical system.

-

How do I install indicator lights and signal towers?

Follow the manufacturer’s installation instructions, ensuring proper wiring and mounting. Indicator lights are typically installed in control panels, while signal towers are mounted in locations where visibility and audibility are crucial.

-

What is the difference between a timer and a PLC?

A timer performs simple time-based control tasks, such as turning a device on or off after a set period. A PLC is a programmable device capable of complex logic operations, used for automating multi-step processes.

-

What kind of warranty do you offer?

We provide warranties that vary by manufacturer and product type. Typically, warranties range from 1 to 3 years, covering defects in materials and workmanship.

-

Are your products compatible with international standards?

Yes, all products offered by BaltElec adhere to European and international standards, ensuring compatibility and safety across various applications and regions.