3214047 - PTI 4-PE/L/NT - Phoenix Contact

The 3214047 - PTI 4-PE/L/NT is fashioned to serve the requirements of technical experts, such as panel builders, electrical fitters, maintenance companies, and original manufacturers. 3214047 presents unmatched efficiency and profit for designers in the power systems industry. This PTI 4-PE/L/NT and other Terminal Blocks, Cable Ends from Phoenix Contact are on offer the best price and procurement time through BaltElec website, a reliable provider assisting industry experts in their sourcing needs.

Users who have bought Phoenix Contact Terminal Blocks, Cable Ends have habitually applauded the creator's trustworthiness. It has been highlighted that the excellent efficiency of 3214047 - PTI 4-PE/L/NT extends to a diverse range of applications. Its supreme attributes make it suitable for various requirements, guaranteeing the success of your industrial, tertiary, and automation contracts.

Our experts concentrates in meeting industrial and tertiary professionals’ needs. We grasp the specific expectations and anticipations of our consumers in the sector. By partnering with our team, your company access access to the superior price lists and delivery schedule of premium products like 3214047 - PTI 4-PE/L/NT from Phoenix Contact at a budget-friendly price. Account holders enjoy extra discounts and dedicated support.

Get started and buy 3214047 - PTI 4-PE/L/NT at our verified and intuitive online store. Don't delay in making this clever resolution that guarantees the utmost quality and satisfies the specific criteria of buyers like your outfit.

Should you experience any issues or concerns about 3214047 - PTI 4-PE/L/NT or any other Phoenix Contact products, drop us a line or refer to our Common Questions section below. We have brought together answers to habitual uncertainties to benefit you further in making an well-informed decision about industrial and tertiary electrical components.

Remember, 3214047 - PTI 4-PE/L/NT from Phoenix Contact is sure, low-cost, and excellent to other brands in the Terminal Blocks, Cable Ends category. Feel free to make it a part of your apparatus instantly. Get at Baltelec e-shop, your trusted partner for all your Phoenix Contact.

In our Baltelec.eu web store you will come across PTI 4-PE/L/NT - 3214047 worth 3.77 €, which will be a steadfast and new solution for your necessities. This article is constructed by the Phoenix Contact brand using the modern technologies and complies with the pinnacle standards of defense and capacity. We deliver articles from the Terminal Blocks, Cable Ends category that merge resilience and usability, which is an excellent preference for various uses. Independent of whether you seek appliances for small assembly or for proficient industrial exploitation, PTI 4-PE/L/NT will be a steadfast associate in your job.

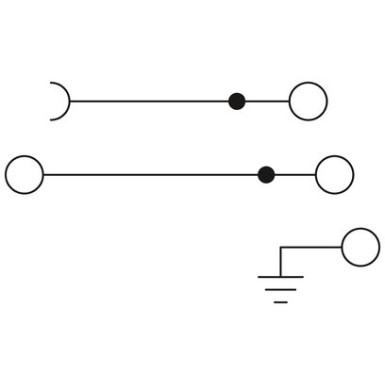

Baltelec endeavors to make the securing process as uncomplicated and fast as workable for our patrons. We offer detailed portrayals and high-quality visuals of PTI 4-PE/L/NT so that you can make an knowledgeable choice. A team of professionals is always ready to help you with any concerns in the Terminal Blocks, Cable Ends section connected to the electing and use of equipment. We are sure that PTI 4-PE/L/NT will meet your needs and become an imperative element of your device for just 3.77 €.

FAQ about 3214047:

-

Why should I buy 3214047 - PTI 4-PE/L/NT from Baltelec website?

When purchasing Phoenix Contact 3214047 from Baltelec online store, you obtain authentic quality Phoenix Contact Terminal Blocks, Cable Ends products at the most competitive prices and turnaround time. Moreover, loyal buyerstake pleasure in additional savings and priority service.

-

How can I determine if 3214047 is the right choice for my undertaking?

To ensure that 3214047 meets the requirements of your drawings, we provide detailed details regarding product's specs, technical characteristics, and interoperability. You can access this information on the specific page of the item model. If you require more guidance, our support team team is prepared to help you in reaching an informed choice.

-

Which warranty coverage is offered for 3214047?

Baltelec.eu team is committed to the reliability of the items we distribute. The regular warranty coverage for Phoenix Contact Terminal Blocks, Cable Ends including Phoenix Contact PTI 4-PE/L/NT is 12 months. Nevertheless, it varies according to the individual item, category, and might be longer. You can discover comprehensive guarantee details on the 3214047 dedicated page or by contacting our support team team.

-

Do you arrange international shipping for Phoenix Contact PTI 4-PE/L/NT including other Phoenix Contact items?

Certainly. Besides serving Estonia, Latvia, Lithuania and other European Union countries, we provide worldwide shipping for Phoenix Contact PTI 4-PE/L/NT. Please note that shipping options, costs, and shipping times might differ depending on the shipping location. In the case of complex orders, kindly contact Baltelec.eu sales representatives.

-

Do Phoenix Contact MBC provided by BALTELEC comply with global norms for safety and reliability?

Certainly. All Phoenix Contact products available at Baltelec.eu online store conform to global standards such as IEC 60898-1 standard and carry the CE mark. These norms guarantee that the items meet stringent security, technical, reliability, and functional criteria.

-

Can Baltelec.eu offer guidance on integrating renewable energy solutions, such as solar energy systems or wind power converters, into my projects?

Certainly! Baltelec online store recognizes the importance of clean energy incorporation within projects. Our team of specialists can support you in choosing the right Phoenix Contact products, to incorporate them into your renewable energy projects}. We can offer recommendations on combining solar energy systems, wind power converters, and additional sustainable options to maximize energy generation and efficiency.

-

Do you have eco-friendly options available within the Terminal Blocks, Cable Ends category to encourage energy conservation efforts?

Definitely!Yes! Baltelec.eu online store provides a wide range of eco-friendly solutions in the category of Terminal Blocks, Cable Ends that are in line with green energy initiatives. Our brand's Phoenix Contact products, including the PTI 4-PE/L/NT, are designed with environmental friendliness in mind. By incorporating these products into your electrical system, you can maximize energy usage and lower environmental impact. Additionally, we provide competitive pricing for our green Phoenix Contact products,, making them an budget-friendly choice for advocating sustainability.

-

Is PTI 4-PE/L/NT offered by Baltelec.eu authentic?

Absolutely, we exclusively sell original Phoenix Contact products, including but not limited to PTI 4-PE/L/NT. We procure our products only through official distribution channels to guarantee their authenticity and high performance.