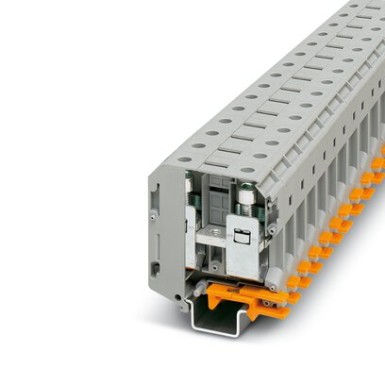

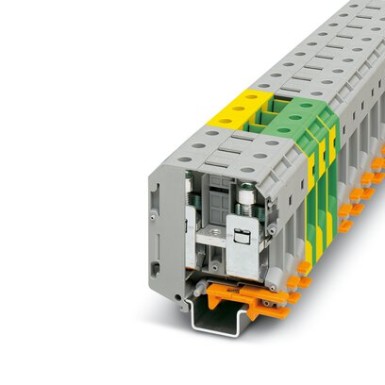

3213140 - UKH 70 - Phoenix Contact

The 3213140 - UKH 70 is engineered to match the prerequisites of business buyers, such as panel builders, electrical installers, facility upkeep providers, and original manufacturers. 3213140 presents impressive excellence and advantages for technicians in the power management industry. This UKH 70 and other Terminal Blocks, Cable Ends from Phoenix Contact are accessible at the most favorable cost and supply period through BALTELEC, a reliable supplier serving tradesmen in their acquisition needs.

Clients who have selected Phoenix Contact Terminal Blocks, Cable Ends have regularly applauded the producer's reliability. It has been noted that the superior workmanship of 3213140 - UKH 70 extends to a extensive scope of operations. Its top-notch components make it well-suited solution for diverse needs, ensuring the success of your industrial, tertiary, and automation projects.

Our team focuses in meeting industrial and tertiary professionals’ needs. We get the special requirements and demands of our consumers in the niche. By aligning with our experts, your company secure access to the premier pricing and availability of first-rate products like 3213140 - UKH 70 from Phoenix Contact at a budget-friendly price. Registered users appreciate extra discounts and expedited requests handling.

Get started and procure 3213140 - UKH 70 at our well-established and intuitive website. Don't delay in making this prudent plan that guarantees the best quality and addresses the defined needs of users like yourselves.

In case you have any concerns or concerns about 3213140 - UKH 70 or any other Phoenix Contact products, get in touch with us or refer to our Frequently Asked Questions section below. We have collected answers to usual questions to guide you further in making an informed decision about industrial and tertiary electrical components.

Remember, 3213140 - UKH 70 from Phoenix Contact is safe, cost-effective, and exceptional to industry peers in the Terminal Blocks, Cable Ends category. Make it a part of your apparatus without delay. Snap up at BALTELEC, your reliable source for all your professional electrical equipment and automation needs.

In our Baltelec.eu online store you will uncover UKH 70 - 3213140 worth 15.86 €, which will be a secure and new solution for your requirements. This product is designed by the Phoenix Contact brand using the up-to-the-minute technologies and meets the peak standards of guarding and competence. We offer commodities from the Terminal Blocks, Cable Ends category that integrate strength and workability, which is an premium selection for various tasks. Regardless of whether you necessitate appliances for small manufacturing or for skilled industrial utilization, UKH 70 will be a reliable aide in your project.

Baltelec aims to make the procuring process as convenient and fast as doable for our consumers. We offer detailed reports and high-quality shots of UKH 70 so that you can make an informed choice. A team of virtuosos is always ready to help you with any enquiries in the Terminal Blocks, Cable Ends section involved to the nomination and use of goods. We are persuaded that UKH 70 will meet your hopes and become an needed element of your inventory for just 15.86 €.

Frequently Raised Questions about Phoenix Contact UKH 70:

-

Why should I order Phoenix Contact UKH 70 from Baltelec.eu online store?

When purchasing 3213140 from BALTELEC, you receive authentic quality Phoenix Contact Terminal Blocks, Cable Ends products at the best prices and delivery schedule. Furthermore, our buyersreceive further discounts and first-class attention.

-

Who can consult if 3213140 is suitable for my undertaking?

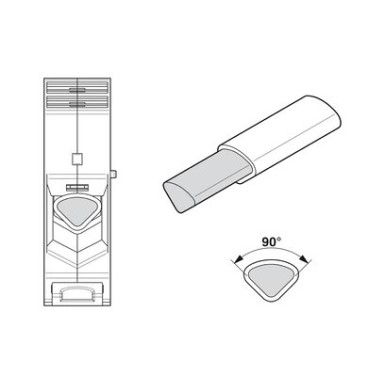

To ensure that 3213140 - UKH 70 is appropriate for your use case, we provide detailed details concerning product's specs, technical characteristics, and in some cases 3D models as well. You can access this information on the specific page of the item model. If you require further assistance, our support team representative is prepared to help you in reaching an educated decision.

-

Which guarantee coverage is provided for Phoenix Contact 3213140?

Baltelec website emphasizes the reliability of the items we deliver. The default guarantee coverage for Phoenix Contact Terminal Blocks, Cable Ends including 3213140 is 12 months. Nevertheless, it is subject depending on the individual product, category, and may even be extended. You can locate specific guarantee details on the Phoenix Contact 3213140 product page or by contacting our support team team.

-

Do you offer worldwide shipping for 3213140 and other Phoenix Contact products?

Yes. Apart from catering to Estonia, Latvia, Lithuania and other European Union countries, we provide international shipping for 3213140 - UKH 70. However that shipping options, costs, and delivery schedule may vary based on the shipping location. For volume requests, feel free to reach out to Baltelec.eu sales representatives.

-

Do Phoenix Contact MBC provided by Baltelec.eu meet global standards for security and reliability?

Of course. All Phoenix Contact products available at BALTELEC online store conform to global standards such as IEC 60898-1 and carry the CE certification. Such standards guarantee that the products meet stringent safety, technical, dependability, and functional requirements.

-

Can Baltelec.eu provide guidance on integrating renewable energy solutions, such as solar power systems or wind power converters, into my projects?

Yes, sure! Baltelec online store understands the importance of sustainable energy incorporation within community. Our group of specialists can help you in choosing the right Phoenix Contact products, to incorporate them into your renewable energy solutions}. We can offer recommendations on integrating solar energy systems, wind power converters, and other sustainable options to maximize power generation and efficiency.

-

Do you have eco-friendly options offered within the Terminal Blocks, Cable Ends category to promote energy conservation efforts?

Definitely!Yes! Baltelec.eu online store offers numerous eco-friendly solutions within the Terminal Blocks, Cable Ends category that are aligned with environmental sustainability objectives. Our brand's Phoenix Contact products, like the 3213140, are crafted with energy conservation in mind. By incorporating these products into your electrical system, you can optimize energy usage and reduce environmental impact. Additionally, we provide attractive pricing for our green Phoenix Contact products,, making them an budget-friendly choice for supporting sustainability.

-

Are UKH 70 offered by BALTELEC legitimate?

Indeed, we exclusively offer original Phoenix Contact products, including but not limited to 3213140. We procure our products exclusively through official distribution channels to assure their genuineness and excellent performance.