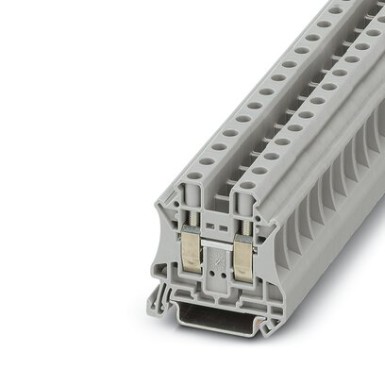

3044160 - UT 10 - Phoenix Contact

The 3044160 - UT 10 is produced to respond to the demands of professional buyers, such as panel builders, wiring specialists, facility upkeep providers, and primary equipment suppliers. 3044160 furnishes exceptional quality and value for technicians in the automation and control industry. This UT 10 and other Terminal Blocks, Cable Ends from Phoenix Contact are available at the unbeatable price and delivery period through BALTELEC, a well-known distributor serving industry experts in their obtaining needs.

Consumers who have acquired Phoenix Contact Terminal Blocks, Cable Ends have steadily commended the manufacturer’s reliability. It has been outlined that the impressive workmanship of 3044160 - UT 10 extends to a spectrum of operations. Its elite specifications make it optimal to satisfy a wide array of needs, assuring the success of your industrial, tertiary, and automation ventures.

BaltElec centers in serving industrial and tertiary professionals’ needs. We understand the distinct needs and standards of our clients in the sector. By partnering with BALTELEC, you receive access to the best pricing and delivery schedule of the top-of-the-line products like 3044160 - UT 10 from Phoenix Contact at cost-effective price. Account holders benefit from additional savings and exclusive assistance.

Act now and secure 3044160 - UT 10 at our risk-free and streamlined internet shop. Don't delay in making this sensible choice that certifies the superior quality and addresses the unique specifications of vendors like your group.

If you encounter any doubts or concerns about 3044160 - UT 10 or any other Phoenix Contact products, reach out to us or refer to our Help section section below. We have compiled answers to regular questions to support you further in making an thoughtful decision about industrial and tertiary electrical components.

Remember, 3044160 - UT 10 from Phoenix Contact is trustworthy, inexpensive, and top-notch to other manufacturers in the Terminal Blocks, Cable Ends category. Make it a part of your apparatus right now. Shop with confidence at Baltelec webstore, your faithful dealer for all your professional electrical equipment and automation needs.

In our Baltelec.eu cyber store you will discover UT 10 - 3044160 worth 0.86 €, which will be a safe and up-to-date solution for your demands. This product is constructed by the Phoenix Contact brand using the up-to-the-minute technologies and adheres to the highest standards of security and efficacy. We extend commodities from the Terminal Blocks, Cable Ends category that merge resilience and usefulness, which is an excellent possibility for various objectives. In defiance of whether you need appliances for small construction or for expert industrial implementation, UT 10 will be a secure adjunct in your project.

Baltelec labors to make the attaining process as accessible and fast as accomplishable for our consumers. We offer detailed explanations and high-quality depictions of UT 10 so that you can make an well-informed choice. A team of adepts is always ready to help you with any questions in the Terminal Blocks, Cable Ends section referencing to the picking and use of supplies. We are confident that UT 10 will meet your standards and become an crucial element of your apparatus for just 0.86 €.

What People Ask about 3044160 - UT 10:

-

Why should I buy Phoenix Contact UT 10 from BaltElec?

When you buy Phoenix Contact UT 10 from Baltelec website, you receive genuine high-quality Phoenix Contact Terminal Blocks, Cable Ends products at the unbeatable prices and delivery schedule. Moreover, registered accountsenjoy additional savings and expedited requests handling.

-

How do I know if Phoenix Contact 3044160 suits for my project?

To ensure that Phoenix Contact 3044160 is appropriate for your drawings, we provide comprehensive details regarding product's technical specifications, technical characteristics, and compatibility. You can access this information on the product page of the product name. If you need more guidance, our customer service representative is prepared to assist you in reaching an educated decision.

-

What warranty coverage is provided for Phoenix Contact UT 10?

BALTELEC emphasizes the reliability of the items we sell. The standard warranty coverage for Phoenix Contact Terminal Blocks, Cable Ends including Phoenix Contact UT 10 is 12 months. However, it is subject depending on the specific item, category, and might be longer. You can find specific warranty information on the 3044160 dedicated page or by reaching out to our customer support team.

-

Can you offer worldwide shipping for 3044160 - UT 10 and other Phoenix Contact products?

Certainly. Apart from catering to Estonia, Latvia, Lithuania and other European Union countries, we offer international shipping for 3044160. Please be aware that delivery options, costs, and delivery schedule can differ depending on the destination. For volume acquisitions, kindly contact Baltelec.eu sales representatives.

-

Do Phoenix Contact MBC provided by Baltelec.eu comply with global standards for safety and reliability?

Completely. All Phoenix Contact items available at Baltelec web store meet international norms such as IEC 60898-1 standard and carry the CE certification. These standards guarantee that the products fulfill stringent safety, technical, reliability, and performance criteria.

-

Can Baltelec.eu provide assistance on integrating renewable energy solutions, such as solar energy systems or wind power converters, into my projects?

Yes! BaltElec recognizes the importance of sustainable energy incorporation within community. Our team of experts can assist you in choosing the appropriate Phoenix Contact items, to incorporate them into your renewable energy projects}. We can provide advice on integrating solar power systems, wind energy converters, and alternative sustainable options to optimize energy generation and effectiveness.

-

Are there energy-efficient options available within the Terminal Blocks, Cable Ends category to support green energy initiatives?

Absolutely! Baltelec.eu online store offers various energy-efficient solutions in the category of Terminal Blocks, Cable Ends that are aligned with energy-saving goals. Our brand's Phoenix Contact products, such as the UT 10, are engineered with environmental friendliness in mind. By incorporating these products into your electrical system, you can enhance energy usage and reduce environmental impact. Additionally, we provide affordable pricing for our energy-efficient Phoenix Contact products,, making them an economical choice for promoting sustainability.

-

Is 3044160 offered by BaltElec e-shop genuine?

Indeed, we only provide original Phoenix Contact products, including UT 10. We procure our products solely through official distribution channels to assure their legitimacy and high standards.